We utilize special materials and precise design capabilities to provide disc springs that meet a high level of precision.

We are proud of our track record as a leading manufacturer, and our products are used even in niche areas where processing is difficult.

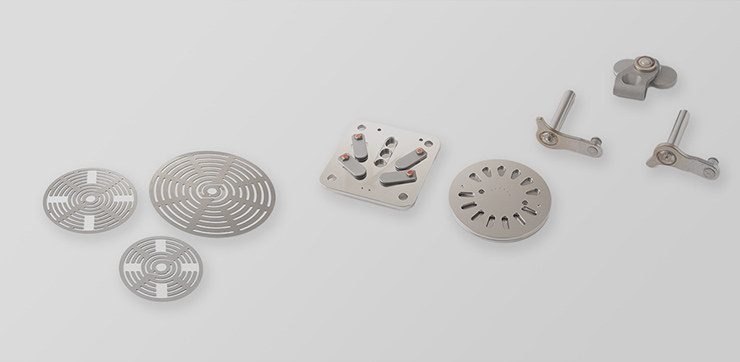

A disc spring is a thin plate bent into a disc shape. When a force is applied to a disc spring it deforms into a flat shape and then returns to its original shape, which is the spring action.

Disc springs can obtain large loads in a small space. In addition, by changing the arrangement of the disc springs, such as stacking them in parallel or in series, depending on the load and force balance, even one type of disc spring can be adapted to various spring characteristics.

DPI boasts approximately 50 years of history and achievements as a leading manufacturer of disc springs. In particular, our main feature is that we use SUP10.

SUP10 is a hard material with good hardenability and high toughness. Because it is a difficult-to-obtain material, it is rarely used in disc springs. However, as a member of the Daido Steel Group, we have access to these materials, so we can provide disc springs that are resistant to breaking when bent.

Most disc springs on the market meet the Japanese Industrial Standards (JIS). However, we have our own standard called the DPI Standard, and we provide products that are used in niche areas that cannot be covered by the JIS.

Our disc springs are mainly used in vertical machining centers, a type of machine tool, as well as valve rotators and water gates used in ship engines.

Features of our disc springs

-

Vertical machining center, machine toolsWe provide “precision disc springs” that can handle high cycles.

Our disc springs are used in the spindle cranks of vertical machining centers. Spindle cranks are called precision springs because they support high rotations of 30,000 times, and they must be extremely precise.

-

Valve rotatorsWe take advantage of our processing technology and are able to handle high-mix low-volume production.

Our disc springs are also used in the valve rotators of marine engines. Our various processing technologies, such as processing grooves in disc springs, allow us to flexibly respond to high-mix low-volume production. We also have a reputation for our vertically integrated production system, including heat processing.