Industrial compressor

We carry out integrated production of suction and discharge valves, which are the main components of compressors.

We manufacture reciprocating compressors used by power companies and others.

A compressor, also known as a compression machine, is a device that compresses fluids such as gases and liquids.

An industrial reciprocating compressor is one such compressor, which sucks air (gas) into a cylinder, compresses it, and then discharges it through the reciprocating motion of a piston inside the cylinder.

Large compressors are used in power companies (power plants), factories, etc. because they can compress gas with pressure.

Compressors for railway vehicles are used to open and close doors and raise and lower pantographs.

Since its founding, DPI has been manufacturing suction and discharge valves, which are the main parts of reciprocating compressors. Therefore, we have a wide range of know-how.

All of our technology is focused on producing thin, strong, and flat parts.

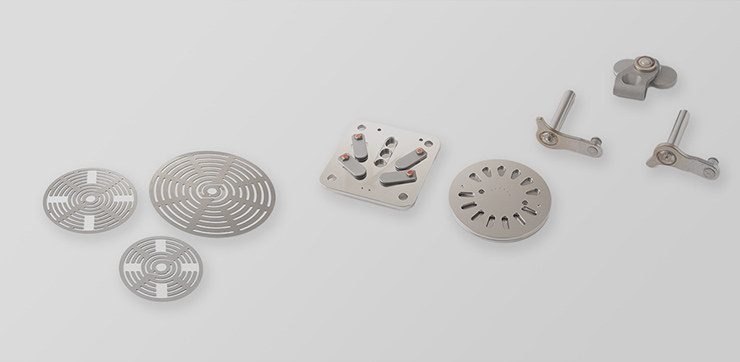

We manufacture valve parts that are essential for compressors.

A reciprocating compressor incorporates several plate parts. We produce these parts in an integrated manner, from cutting to grinding, press processing, heat treatment, barrel processing, and assembly.

The valve plate plays the role of a valve by being linked to the flow of air.

When the valve is in the closed position, the plate must remain flat to avoid distortions and scratches to prevent air leakage.

In addition, durability is required as they receive severe impact from other parts during operation.

Therefore, we perform optimal heat treatment to suit the material, increase its strength, and combine technologies such as grinding to satisfy the specifications requested by our customers.