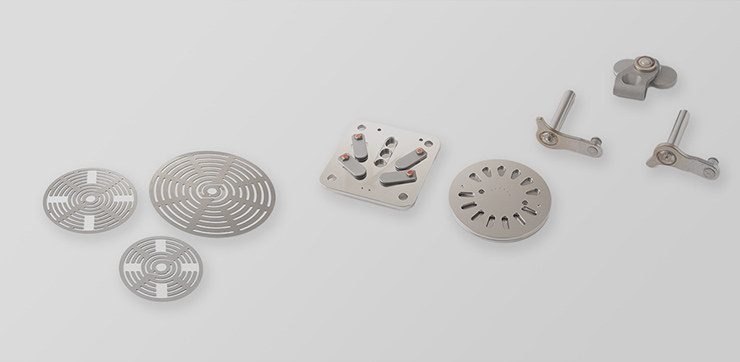

We are developing processing and assembly technology for rotor parts used in fuel cell systems.

DPI is taking on the challenge of processing and assembling rotor parts used in fuel cell systems for fuel cell vehicles (FCVs).

Rotor parts are used at high speeds, so high-precision processing is required. This rotor part uses magnets.

We can process even hard and brittle magnets with high precision.

The problem with magnets is that they are extremely difficult to process and handle.

The magnet is so hard that it can cause the drill bit to fall off when drilling holes. Also, magnets are so fragile that even the slightest impact can cause them to chip. Therefore, advanced processing technology is required.

DPI is able to process magnets with high precision in end-face processing and drilling by making full use of the processing technology cultivated through processing high alloys.

Regarding end-face processing, by paralleling and flattening the surfaces, we achieved an accuracy of less than Ra1.6μm in surface roughness.

In addition, when it comes to drilling a hole, it is now possible to achieve dimensional tolerances in the micron range, making it possible to process highly accurate perfect circles and cylindrical shapes.

Even for these difficult-to-process materials, we use processing techniques that cannot be imitated by others. In this way, we will contribute to the development of next-generation automobiles.

Development product

Magnet processing

| Process | Features | Image 1 | Image 2 |

|---|---|---|---|

| End-face processing |

|

|

|

| Pilot hole drilling |

|

|

|

| Hole boring |

|

|

|

| Drilling finishing process |

|

|

|