Based on the requirements of ISO9001 and IATF16949, our three departments maintain and manage internal and external quality assurance and management systems.

DPI’ Quality Assurance Department is an independent department from the manufacturing department, and has “ISO Office,” “Quality Assurance Section,” and “Quality Control Section.” We have acquired ISO9001 (international standard for quality management systems) and IATF16949 (quality management system for organizations in the automotive industry) certification, and are conducting initiatives based on quality management system requirements.

The Quality Assurance Department strives to maintain and improve quality every day and conducts quality control activities to provide quality that satisfies our customers.

The main duties of the Quality Assurance Department are as follows:

- Dealing with periodic audits and renewal audits conducted by certification bodies in accordance with ISO9001, ISO 14001, and IATF16949 certification.

- Hold monthly quality review meetings and report on quality overview

- Pursue the causes of non-conformities that have occurred within the company and at suppliers (outsourcing companies), formulate measures to prevent recurrence, and confirm the effectiveness of the measures.

- The Quality Assurance Department acts as the point of contact for complaints and responds promptly to customers.

- Continue to maintain the quality control system through regular audits (on-site visits) of a wide variety of suppliers (outsourcing companies)

- Calibration management of various measuring instruments

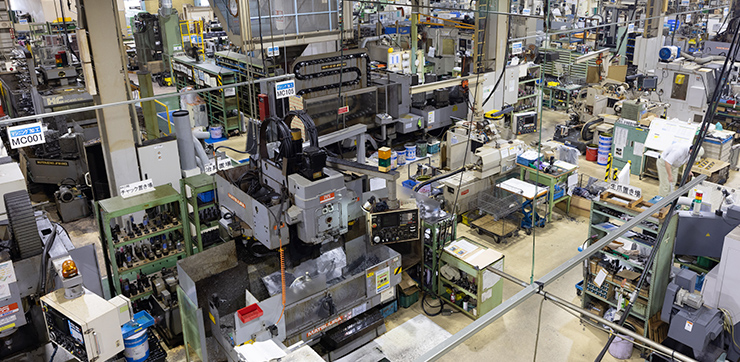

What we place particular emphasis on in our daily quality control is checking our quality control system through “genchi genbutsu (the actual place, the actual part)”.

Additionally, we have established an in-house certification system for in-house inspectors, and only those who have been certified as inspectors will conduct inspections. Therefore, we can maintain inspection level quality and guarantee quality.

Three departments of the Quality Assurance Department

ISO Office

It serves as the point of contact for audits by external auditing organizations such as ISO, while managing internal quality control documents.

Quality Assurance Section

In addition to responding to nonconformities that occur internally and at our suppliers, this section serves as the point of contact for customer complaints. When a nonconformity occurs, we work with the department responsible for the occurrence (including suppliers) to investigate the cause of the occurrence and consider measures to prevent recurrence. Furthermore, the effectiveness of the measures will be confirmed. This office also performs measurement management such as calibration of various measuring instruments.

Quality Control Section

As the department that controls quality audits, this office is responsible for internal audits and audits of suppliers (outsourcing companies).

In addition, when we certify new suppliers (outsourcing companies), we check their quality control systems through “genchi genbutsu (the actual place, the actual part).” We also make requests for improvements as necessary, which ultimately contributes to improving their quality control.

Features of Quality Assurance Department inspections

Our various inspections are carried out by qualified personnel. In other words, the staff engaged in inspection are all qualified inspectors who have gone through a certification period to ensure quality.

In addition, the traceability of the measuring equipment used for inspections has been confirmed, and calibration is performed regularly.

Inspection qualifications certified by the Quality Assurance Department

- Inspectors: Perform general inspection work such as dimension and appearance inspection

- Non-destructive inspectors: Perform non-destructive inspection

- Certification and calibration staff: Perform certification and calibration when calibrating measuring instruments in-house.

- 3D measurement inspectors: Perform 3D measurement inspection

- Hardness inspectors: Perform surface hardness test

- Dynamic balance test inspectors: Perform dynamic balance test

- Leak test inspectors: Perform leak (airtightness) test inspection