Vertically integrated production from material consideration to processing and inspection.

Another strength of ours is that we can leverage the wide range of knowledge of the Daido Steel Group.

We provide vertically integrated production from material procurement to processing and inspection.

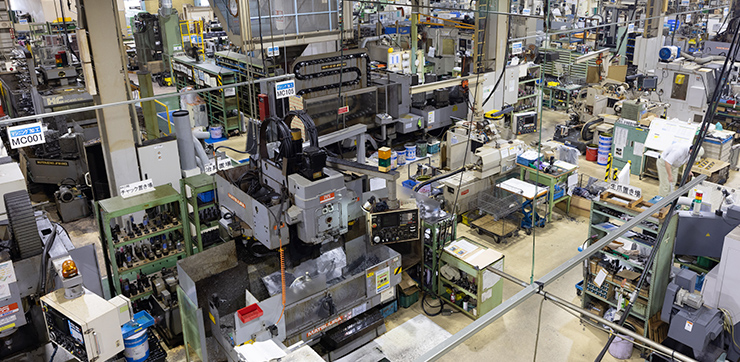

DPI has cutting, grinding, assembly, and heat treatment equipment in its own plant. Therefore, it realizes a vertically integrated production system from material procurement to processing and inspection.

Even materials that are not widely available on the market can be procured by leveraging Daido Steel's group strength.

Another strength of our vertically integrated production is that we are able to utilize our wide network of Daido Steel Group companies and sub-contractor companies to respond to processing requests that cannot be met with our own equipment alone.

Vertically integrated production flow

We listen to the customer's requests, share them with the relevant internal departments along with the customer's diagrams, and move on to the next step.

We consider the optimal material shapes and dimensions for manufacturing and check if they can be procured. If you are having trouble selecting the material to use for your product, we will consider it and suggest a material with the properties that meet your needs.

Based on the customer's diagrams and specifications, we consider a manufacturing process that can satisfy the quality and specification requirements.

We will suggest to our customers where diagrams and specifications need to be changed in order to proceed with the manufacturing process, as well as quality improvement and cost reduction (VE/VA) ideas.

If we receive a new request from a customer, we will consider it again and provide feedback.

As we are a group company of Daido Steel, we have knowledge of a wide range of materials and are able to propose and arrange materials that meet your needs.

As our group includes trading companies, we are able to procure materials and collect information, even for materials that cannot be procured within our group.

We consider processing methods and conditions from every angle. We have a wide selection of processing machines from various manufacturers. Specifically, we have about 50 machines, mainly two types: lathes and machining centers.

We are good at machining difficult-to-cut materials such as heat-resistant materials, and meet customer requests not only in terms of technology but also in terms of quality and cost.

We have equipment for surface grinding and centerless polishing, and are able to grind and finish with high precision in terms of dimensions and surface roughness. We also have barrel polishing equipment, and can perform deburring and surface finishing through barrel processing.

Detailed introduction to grinding

Through quenching, tempering, annealing, solution treatment, aging treatment, sub-zero treatment, etc., we change the properties of steel materials to meet customer requirements.

Detailed introduction to heat treatment

We perform surface treatments according to the required performance. For example, we support various surface treatments such as corrosion resistance, wear resistance, and improved initial conformability.

Detailed introduction to surface treatment

We handle everything from parts manufacturing to assembly.

In addition to simple assembly, we can also handle welding and riveting.

We have acquired ISO9001 and IATF16949 (quality management system for organizations in the automotive industry) certification, and conduct quality control based on quality management system requirements.

Detailed introduction to quality assurance

We handle a wide variety of products, and respond to the needs of a wide variety of customers in various industries both domestically and internationally with our high shipping quality and know-how.